8

Countries served

About Win Corp

Win Corp is a Coimbatore-born consulting partner helping textile entrepreneurs and manufacturers set up, scale, and future-proof factories across the globe – from first machine to steady-state flow.

Win Corp — By the Numbers

8

Countries served

75+

Machinery collaborations

30+

Installation projects

90+

Total projects

Impact & Reach

A proven implementation record across continents, customer segments, and factory scales.

Completed across project consultancy, technology transfer, and machinery installation — delivering predictable outcomes for first-time and seasoned entrepreneurs alike.

From India to Thailand, Indonesia to Egypt, Bangladesh to Vietnam — Win Corp carries best practices across geographies and adapts them to local realities.

Deep relationships with world-class brands from Germany, Italy, Switzerland, Japan, and Korea ensure the right technology fit and long-term support.

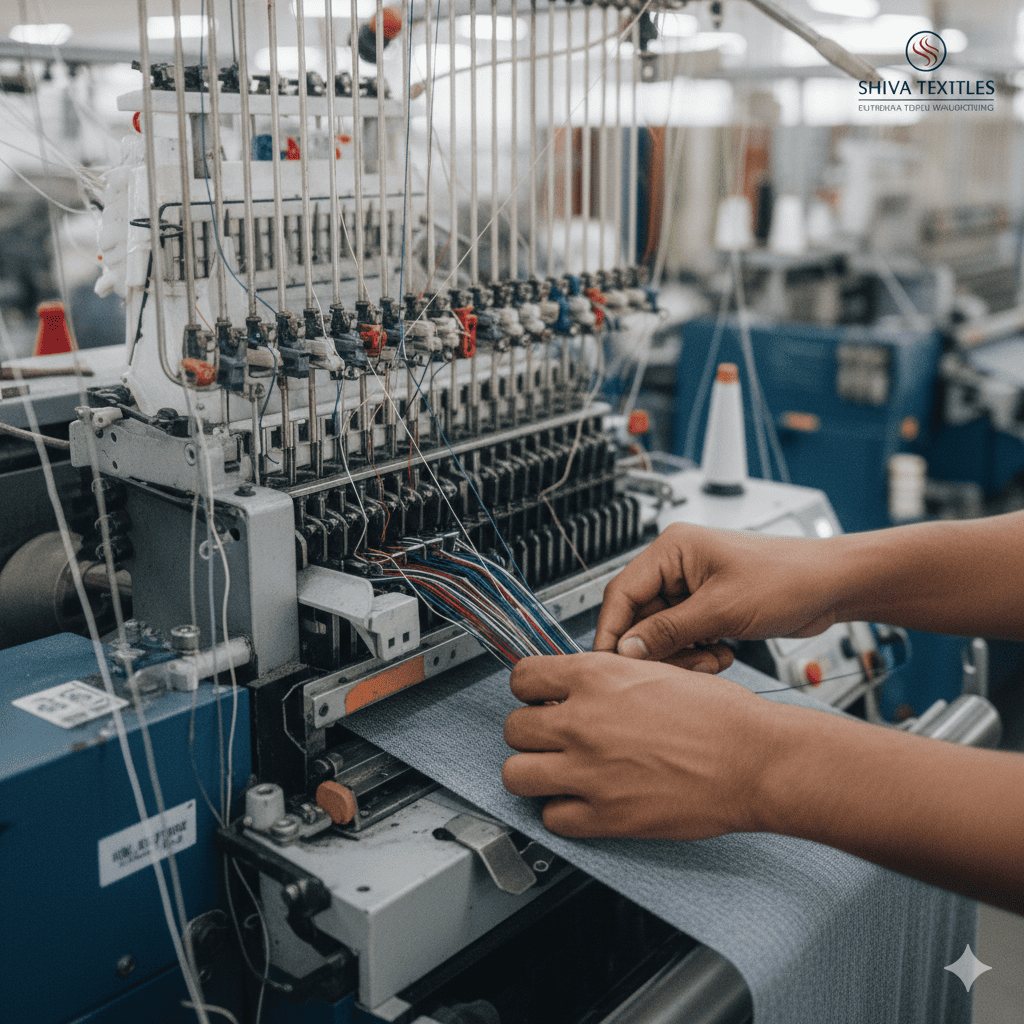

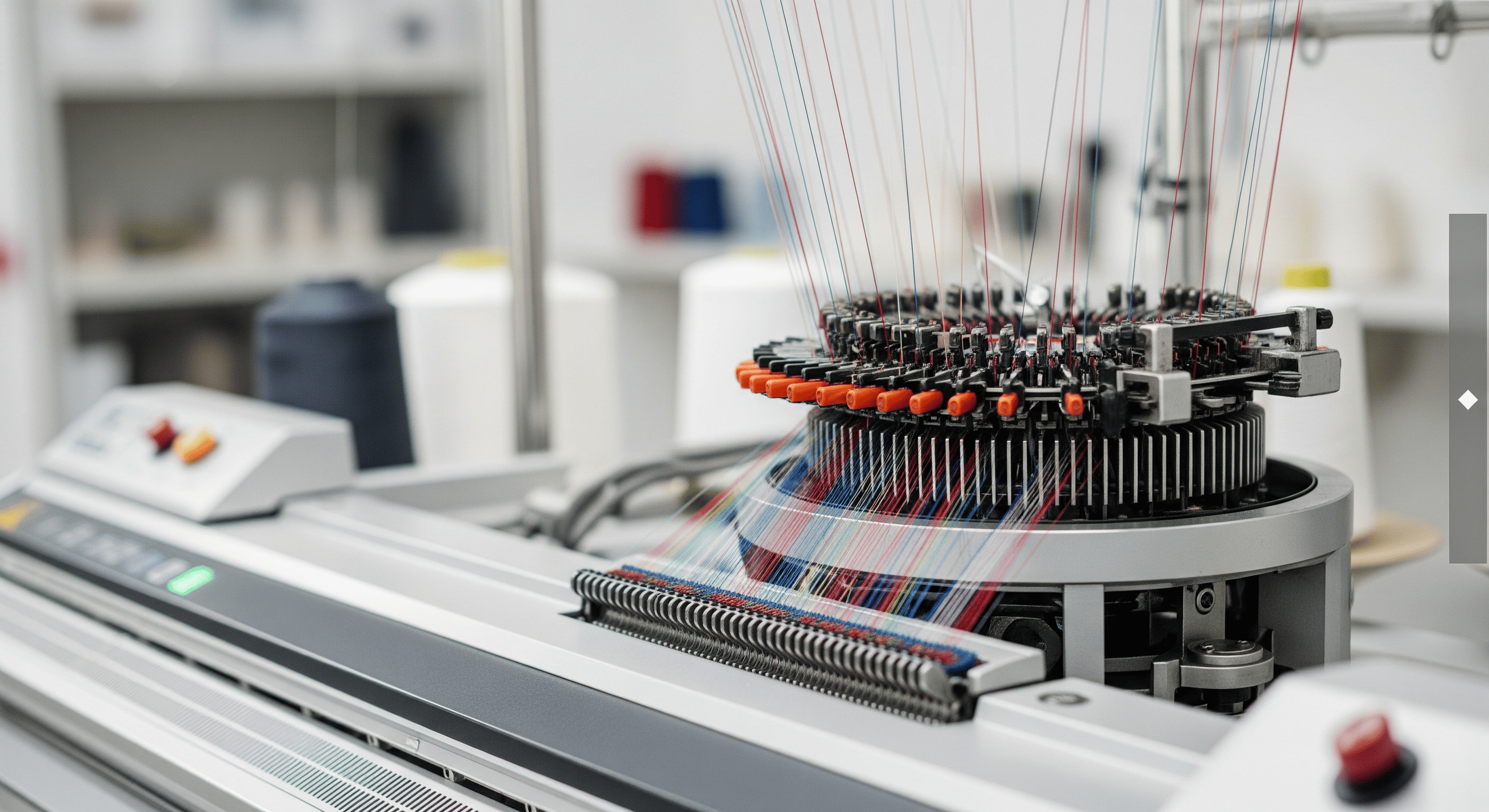

Direct machinery installation, commissioning, and service support delivered globally – aligned to safety, quality, and audit-ready standards.

Expertise Portfolio

30 major implementations including Victus Dyeing(Geena Garments), Cotton Blossom Dyeing & Finishing, Exim Knits and Jeyavishnu Processor(KM Knitwear).

12 international projects across 8 countries elevating teams and processes.

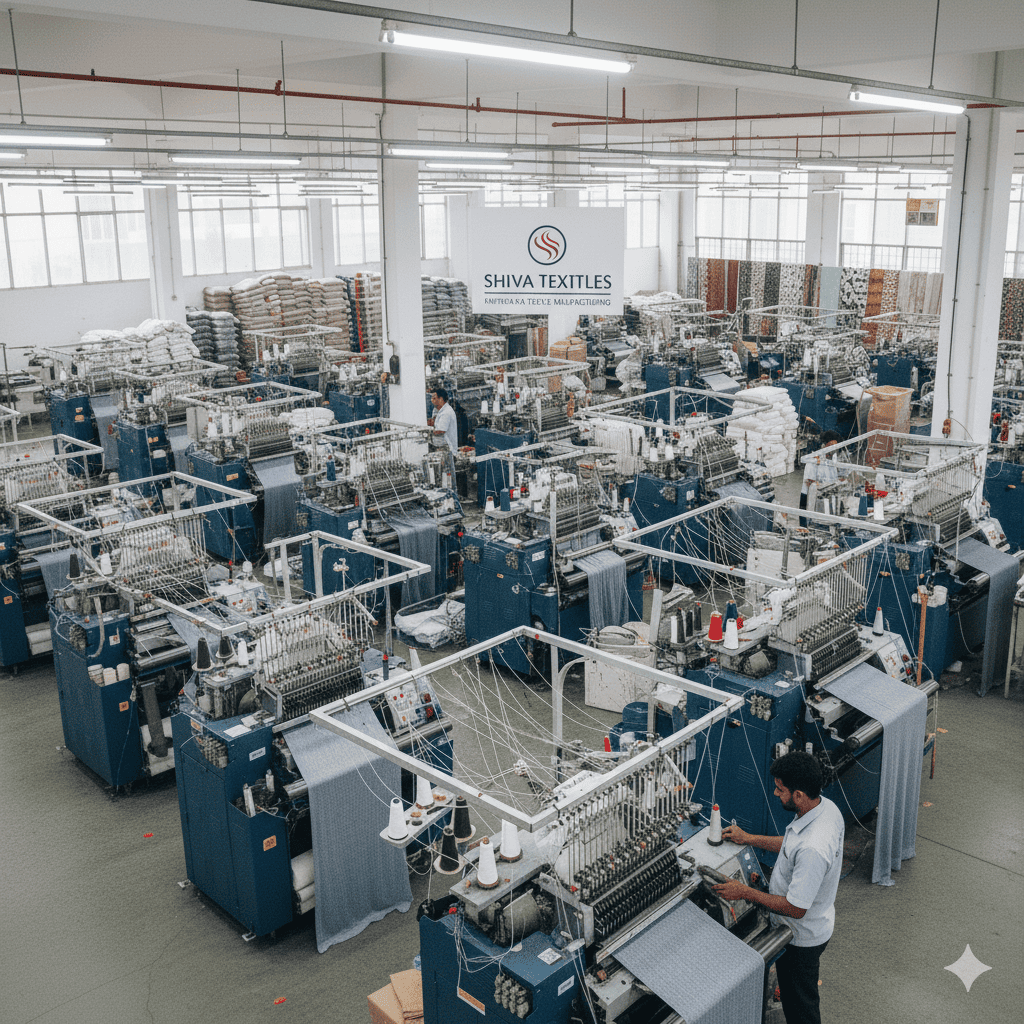

50+ facilities commissioned from knitting to finishing across multiple Indian states.

Geographic Footprint

From Tamil Nadu’s knitwear belt to export-driven hubs in Southeast Asia and Africa.

Major city projects in Mumbai, Kolkata, Chennai, Bangalore, Hyderabad, and Ludhiana.

Multi-country experience ensures cultural sensitivity and region-specific compliance.

Technical Excellence

Experience across 5+ knitting technologies (Mayer & Cie, Terrot, Pailung, Shima Seiki), 6+ pretreatment systems (Dornier, Benninger, Bianco), and 11+ dyeing brands (Thies, Then, Sclavos, Fongs).

13+ finishing equipment types (EHWHA, PoongKwang, Monforts) and 8+ laboratory equipment brands (Mathis, Sedo Treepoint, SDL) for end-to-end process reliability.

19+ utility systems including Thermax, Forbes Marshall, and Atlas Copco – balancing productivity with sustainability and operating costs.

Industry Segments Served

Full-line knitwear implementations for export and domestic brands.

Dyeing, washing, and finishing units engineered for buyer compliance.

Cut-to-pack garment units aligned to audit-ready workflows.

Process houses with robust utilities and shade reproducibility.

Global buyer–driven standards translated into shop-floor systems.

End-to-end plants from fibre to finished fabric and garments.

Trusted by Export Leaders

From India’s largest export houses to focused niche mills, Win Corp is the quiet partner behind factories that run on time, on spec, and on buyer standards.

Leading Export Houses

Tirupur Textile Hub

International Brands

Why These Numbers Matter

Behind every statistic is a factory that needed more than theory – they needed execution.

Every one of the 90+ implementations adds to a living playbook – what works, what fails, and what to avoid in your context. You don’t just get advice; you get patterns that have already been proven in plants like yours.

With 75+ machinery collaborations and 30+ installations, Win Corp operates inside a mature ecosystem of OEMs, vendors, and service teams – reducing your risk on spares, service, and technology upgrades.

From startup knit units to large integrated mills, from export houses to process-only plants – the mix of industry segments served means solutions are tuned to your scale, not copy–pasted from elsewhere.

Work across 8 countries brings in global best practices. Those are then filtered through local realities – labour, power, water, compliance so your plant is world-class without being unrealistic.